Bolted Joint Assemblies

A course designed by HYTORC USA and HYTORC Pakistan IBS with reference to ASME and OSHA principles.

Pressure Vessels and Piping

Oil, Gas and Chemical Refining/Production

Fertilizers, Fossils and Nuclear Power

Generation

Pipelines, Heat Exchangers, Boilers and

Pumps

Mechanical Joints

Wind Power Erection and Maintenance

Mining and Heavy Equipment

Generators and Heavy Equipment

Steel Mills, Paper Mills, Railroads etc.

Structural Joints

Steel Erection

Building and Permanent Fixtures

Towers and Bridges

BENEFITS / OUTCOMES OF THE TRAINING

- Work Culture improvement by utilization of latest bolting technology.

- Technical team will be able to execute erection and maintenance activities without the need for a Hammer and Back-up wrench.

- Effectively saving 50% Time with enhanced management of industrial resources after getting proper knowledge and guidance through this training.

- Greatly enhanced Safety of plant equipment and personnel and helped them in improving working Culture

- Problem solving and on-site solution tactics ability.

- Never having to revisit an exchanger or pressure vessel for carrying out compromising exercise of Hot Bolting.

- Never having a bolting related unscheduled due to no leaks despite thermal shocks.

- Team conformed with latest ASME standards.

- Minimizing downtime in industry by adopting correct and effective procedures for dis-assembly and assembly operations.

- Enhancing Accuracy and precision during bolting operations giving more confidence to Maintenance Team.

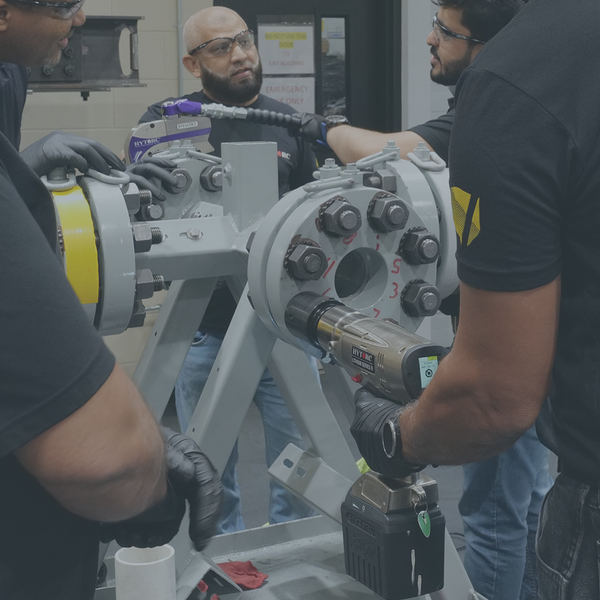

- Practical Application and comprehending operation of tools and equipment.

- Hands on Experience with practical demonstration of hydraulic bolting techniques.